In today’s fast-paced and competitive food manufacturing industry, companies are constantly seeking ways to enhance efficiency, reduce costs, and maintain high-quality standards. Out of all the latest digital assets, food manufacturing software development has emerged as a profitable business service.

Whether you need to manage your inventories, get real-time data on market analytics and demands, safely store your secret recipes, or even do QC of the food, everything is possible via custom food manufacturing software.

So, if you plan to create one for your business, you have landed in the right place! This comprehensive blog post will explore what food manufacturing software is, its benefits and market scenario, key features, and the process of food manufacturing software development!

What is Food Manufacturing Software?

Food manufacturing software is a digital solution designed to streamline and automate various processes involved in the production and distribution of food products. It encompasses a range of modules that cover areas such as inventory management, recipe formulation, quality control, traceability, compliance, scheduling, and resource planning.

The software serves as a centralized platform that facilitates seamless communication and coordination across different departments, resulting in improved productivity and operational efficiency.

Why Invest in Food Manufacturing Software Development?

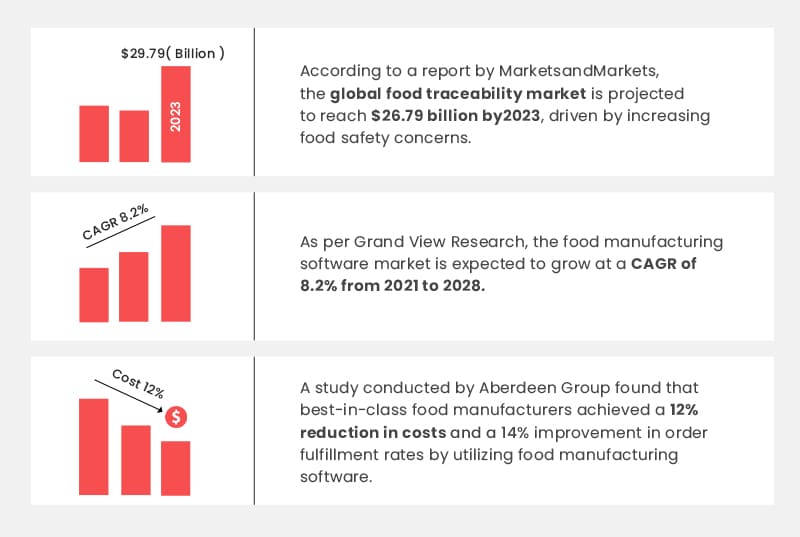

Food manufacturing software is not a new concept in the market. However, with the advent of next-gen technologies like AI, ML, and cloud, this profitable concept accerated quickly. Here’s the market scenario for developing the food manufacturing software:

But why are companies investing in this enterprise solutions? Well, there are several benefits that have lured leading organizations to invest in food manufacturing software development. Let’s explore the best ones below:

Enhanced Efficiency

Enhanced Efficiency

There are numerous tasks in the food manufacturing process that are repetitive and take up much time to complete. Such tasks can be completed if you decide to custom-build food manufacturing software. It will add the power of automation for dealing with repetitive tasks and lead to saving your time and increasing productivity.

Improved Quality Control

Improved Quality Control

You understand that for any manufacturing process to be successful, it is absolutely essential to check the quality of the product. By investing in food manufacturing software development, you will gain assurance about your product’s quality control. The software can offer you real-time monitoring data analysis to ensure that the products are aligned with your desired quality standards.

Enhanced Traceability

Enhanced Traceability

Another reason why you should invest in food and beverage manufacturing software development is to enhance your traceability. The software can help you to track and trace the raw materials, ingredients, and finished products throughout the supply chain. It will keep you up to date with the entire elements required to make your manufacturing procedure successful.

Inventory Optimization

Inventory Optimization

The next component that plays a crucial step in your manufacturing process is inventory. In order to keep an eye on every single demand, reduce the wastage of raw materials and manage stockouts, inventory needs to be optimized. It can be easily done by leveraging the food manufacturing software.

That’s why food manufacturing software development has become a hot trend of the food industry. If you wish to invest in such a solution, then it is the right time!

Food Manufacturing Software Development- Top Features

So, after exploring the top benefits, you have finally decided to invest in this solution. But there are many things that one has to focus on while custom manufacturing software development.

Let’s start with the most critical one, which are features.

Choosing the best features can be daunting, especially for the ones who are new to the software development field. Well, that’s what experts are for! Our experts have developed and delivered many similar solutions for the food industry, and we can do that for you too! To offer you clarity here, we have listed the top features that you should include in your custom food manufacturing software solution.

Inventory Management

By incorporating the feature of inventory management within your food and beverage manufacturing software, you can enhance its efficiency. You will be able to manage your inventory by tracking, controlling, and optimizing the raw materials, ingredients, and finished goods. Your software will offer you real-time visibility and allow monitoring of the quantity, location, and status of each item in the inventory.

Also Read: How Inventory Management Software Development Can Help Overcome Business Challenges?

Recipe Formulation

Recipe formulation is another crucial feature that will add value to your food manufacturing software development process. It will allow the creation, management and optimization of the recipes or formulas for food products. Integrating this feature within your software will gain you access to the relevant detailed information about each ingredient used within the recipes.

Quality Control and Compliance

Next feature that you consider of integrating within your food manufacturing software is quality control and compliance. With this feature your software will be able to ensure adherence to industry regulation, product safety and high-quality standards. You should integrate this feature when your custom builds your software solution, as it will provide a platform to define and manage a comprehensive quality control plan. It also managed non-conformances or deviations from quality standards.

Traceability and Lot Tracking

Another feature that will add value to your food manufacturing software development project is traceability and lot tracking. It helps in identifying and tracking the ingredients, batches, and finished products throughout the supply chain. It enables the system to establish traceability from the moment the ingredients are received. Each lot or batch number serves as a unique identifier that can be tracked throughout the production process.

Scheduling and Resource Planning

The next crucial feature that can add advancement to your custom food manufacturing software solution is scheduling and resource planning. It will allow you to make efficient production planning, optimization of resources, and effective utilization of equipment and personnel. It will also allow you to define production orders, assign them to specific product lines or workstations, and allocate time slots for each order.

How to Develop Food Manufacturing Software?

So, we are at the most critical and much-awaited section of our blog post – the process for food manufacturing software development. Although the creation of food manufacturing software is also a complex task, you can make it easy by partnering with a reputable custom software development company and following the steps mentioned below:

Understand Your Target Audience and Define Your Requirement

The first thing that you need to do is to understand who your target audience is going to be. Your users are going to be the ultimate reason why you are investing in this project, so you need to be precise about the needs of your target audience.

You need to conduct a comprehensive analysis of the food manufacturing industry to understand its dynamics, trends, and challenges. Identify key players, market size, growth opportunities, and emerging technologies.

Identify the target audience for your software, such as food manufacturers, processors, or distributors. Understand their pain points, challenges, and specific requirements. Gather feedback through surveys, interviews, or focus groups to gain insights into their needs and preferences.

You also need to do a competitor analysis, as it will give you an idea of how to be unique in the market. To attract your target audience, you need to offer them something different than what they already have been served by your competitors. Studying the strategy, goals, and other essentials related to a similar project of your competitor will keep you a step forward than them.

Hire Software Developers for Your Project

Now you have clarity about your ideas after learning about the users you wish to target with food manufacturing software development. But you will require a development team incorporating experts to turn your ideas into reality. This is where you need to leverage the services offered by an experienced software development company.

When you hire developers from an experienced company, there are so many benefits that you can bag. For example, if you hire dedicated developers from Matellio , you will receive a wide range of development services. From offering you consulting and designing to developing the software, we cover it all with perfection. Apart from that, we have experts who can help you with market and competitor analysis. With that, you will have an accurate idea of the latest trends and unique features to incorporate in your food manufacturing software.

Not to mention, the perks of getting all the talented resources under one roof and at flexible pricing models is also possible by partnering with an experienced custom software development company like us rather than freelancers.

Select the Best Tech Stack

To integrate all those unique and advanced features in your software solution, you need to work with various technologies and tools. But similar to features, not many people have the technical knowledge of which tech stack to choose for what purpose. Well, don’t worry, we have got you covered!

Here is the general tech stack for food manufacturing software development:

| Back-end Development | Django (Python), Ruby on Rails, or Node.js |

| Database Management | PostgreSQL or MySQL |

| Front-end Development | ReactJS, Angular, or Vue.js interfaces |

| User Interface (UI) Design | Adobe Photoshop or Sketch |

| Version Control | Git |

To further enhance the capabilities of food manufacturing software, integrating AI APIs and leveraging additional technologies can be beneficial. Here are some examples:

Computer Vision

Computer Vision

APIs like Google Cloud Vision or OpenCV can be used for automating the quality inspection processes and detecting defects or contaminants in food products.

Machine Learning

Machine Learning

ML models can be used for predicting the demand patterns, optimizing inventory management and minimizing waste. The NLP model can be used to automate data extraction from documents, such as supplier invoices or compliance documents.

IoT Integration

IoT Integration

Connecting with the sensors and IoT devices can help in monitoring temperature, humidity, and other environmental factors in real time, ensuring proper storage conditions.

Data Analytics and Business Intelligence

Data Analytics and Business Intelligence

Integrate data analytics tools like Tableau or Power BI to visualize key performance indicators (KPIs), generate insights, and support data-driven decision-making.

Cloud Computing

Cloud Computing

Utilize cloud computing platforms like AWS or Azure for scalability, storage, and data processing capabilities.

Leverage serverless architecture for cost optimization and automatic scaling based on demand.

Learn how IoT in food inventory management software is revolutionizing inventory control and efficiency.

Develop, Test, and Deploy

Now that you have all the resources and a definite pathway through which you can get your food manufacturing software developed, it’s time to take the final turn.

The idea you had for your project is aligned. You have the best development team to convert those ideas, so let the development begin. But now the question arises of which development methodology to choose for getting the best results. Choosing an agile methodology for your software development will be a wise decision.

Adopt an Agile methodology like Scrum or Kanban for iterative development and efficient project management. The method of agile will break down your project into smaller sprints, set clear goals, and prioritize tasks for each sprint.

You will be able to conduct regular meetings and sprint reviews to track progress, address challenges, and adjust project scope as needed.

Once the software is developed it’s crucial to test the same. Make sure that the development company you choose offers you different testing techniques to ensure that your software is smooth with all its functionalities.

At Matellio, we offer both manual as well as automated software testing so that your custom build software serves its purpose. Once your development team is done with the testing part, it’s time to deploy your software on the cloud or the local server as per your requirement.

How Can Matellio Help You with Food Manufacturing Software Development?

Food manufacturing software development offers immense benefits and competitive advantages in an industry driven by efficiency, quality control, and compliance. By investing in a well-designed and feature-rich software solution, you can optimize your operations, reduce costs, enhance traceability, and make data-driven decisions.

Matellio will be the right development partner that can revolutionize your project process and achieve greater success in the dynamic food manufacturing landscape.

We are known as one of the best providers of digital transformation services for various industries. So, our team is upgraded with the latest tools, technologies, and industry trends in the food manufacturing process. Our experts can now easily handle your project and deliver you a high-quality software solution matching the current market standards.

We make sure to follow robust security regulations to keep your data safe. With us by your side, you will not be worrying about your timeline or development cost.

If you have any kind of doubt regarding the development cycle, want to learn about the development cost, and need consulting services to align your ideas, reach out to our experts by filling out this form.

Enhanced Efficiency

Enhanced Efficiency Improved Quality Control

Improved Quality Control Enhanced Traceability

Enhanced Traceability Inventory Optimization

Inventory Optimization

Computer Vision

Computer Vision Machine Learning

Machine Learning IoT Integration

IoT Integration Data Analytics and Business Intelligence

Data Analytics and Business Intelligence Cloud Computing

Cloud Computing